The history of DRIPA and Health and Safety - it's not what you think!

Origins: The Social Justice Imperative -

The establishment of the International Labour Organization (ILO) under Part XIII of the Treaty of Versailles (1919) was a deliberate, strategic act of statecraft based on the profound realization that "universal and lasting peace can only be based on social justice." This mandate was not created in a vacuum but emerged from a long, international lineage of political documents that progressively secured rights and limited arbitrary power.

The journey began with the English Magna Carta (1215), which established the foundational principle of the Rule of Law, binding the sovereign to legal limits. Similar impulses to codify legal authority were seen across the globe, such as in Japan’s Jōei Code (1232), which secured judicial rights for centuries, and in France’s Charte aux Normands (1315), which confirmed regional liberties against central power. This tradition expanded with the American Declaration of Independence (1776), which articulated the universal concept of "unalienable rights"—life, liberty, and the pursuit of happiness.

The ILO’s founding was the synthesis of this legal tradition with the urgent, modern demands of industrial labour movements. It acknowledged that political rights were meaningless without economic security, thereby shifting the global focus from securing freedom from oppression to guaranteeing economic and social rights.

The ILO’s Prime Directive and the Framework of Decent Work

The prime directive of the ILO is to advance social justice by promoting Decent Work for all. Decent Work is the practical application of this ideal, encompassing productive work in conditions of freedom, equity, security, and human dignity.

The ILO realizes this mandate through its Conventions—international treaties that become legally binding upon ratification. These Conventions form the Source Authority for labour rights globally, codifying the right to organize (Convention No. 87), the abolition of forced labour (Conventions No. 29/105), and non-discrimination (Convention No. 100/111).

This commitment to human dignity extends to specific mandates, such as the Indigenous and Tribal Peoples Convention, 1989 (C169). This principle of respecting self-determination and free, informed consent is reflected in Canadian contexts like the Declaration on the Rights of Indigenous Peoples Act (DRIPA), affirming that all fundamental rights—whether cultural or safety-related—are inseparable expressions of social justice.

From Conventions to Management Systems: The Three Tiers

Achieving the ILO’s ideals requires a tiered framework, as an international treaty must be translated into domestic law and then into organizational practice.

ILO Conventions (The Right): Set the global baseline, such as the fundamental right to a safe workplace (Convention No. 155).

National Acts (The Law): Provincial WorkSafe Acts (and their regulations) are the legal tools that translate C155 into mandatory, enforceable duties for Canadian employers. WorkSafe authorities enforce the law, not the ISO standard.

ISO Standards (The Management System): Standards like ISO 45001 (Occupational Health and Safety) and ISO 26000 (Social Responsibility) are voluntary frameworks that help organizations systematically meet the law and go beyond it.

Steelmanning the Argument: Efficiency and Congruence

The core strategic argument for adopting ISO 45001 is that it is the most efficient and congruent method for organizations to realize the ILO's ethical and legal imperatives.

While a company can technically comply with the WorkSafe Act reactively, ISO 45001 requires a proactive management system based on the PDCA cycle. This is congruent with the ILO’s vision because:

It Operationalizes Security: ISO 45001 mandates continuous risk identification and mitigation, translating the abstract right to security (C155) into measurable, preventative processes, moving beyond mere legal compliance.

It Enforces Social Dialogue: The standard requires mandatory participation and consultation of workers in setting OHS policies. This directly realizes the ILO’s ideal of worker agency, demonstrating respect for human dignity across all decision-making, analogous to the consultation requirements of C169 and DRIPA.

In essence, an organization that effectively implements ISO 45001 adopts a world-class system that saves time, reduces risk, and provides auditable proof that it is contributing to the global project of social justice—the very foundation established at Versailles.

Source: Treaty of Versailles (Part XIII: Labour), ILO Constitution, Magna Carta, American Declaration of Independence, Charte aux Normands, Jōei Code, ILO Conventions No. 87, 155, 169, ISO 45001, and ISO 26000.

Halloween - Scary Story When Compassion Kills!

Roberta Ditchcroft aka Bobbi 01-10-01

The Ditchcroft Digger - Intrepid Investigative Journalist: When Compassion Kills (an allegorical story?)

In October 2001, the story was written about the death of Mr. Chen in Brightdale, a quiet town framed by dense northern forests, began as an exposé of corporate negligence. It ended as a terrifying lesson in systemic tokenism. Roberta Ditchcroft, known as Bobbi, viewed her job not as finding mistakes but as finding the patterns that make mistakes inevitable.

The Chain of Negligence

Bobbi's initial story, published despite frantic legal threats against her news outlet, detailed the illegal single-staff night at Bluespruce Manor. Mr. Chen, recently discharged post-surgery, bled out while the lone care aide, Maria, was tending to another crisis. The official line was "unavoidable complication." Bobbi’s report proved it was a calculated corporate risk.

The corporation reacted immediately, initiating a full corporate defence, blacklisting Bobbi, and escalating legal threats. Her editor, fearing the financial collapse of the paper, urged caution. The pressure, however, only confirmed the toxicity of the system Bobbi was reporting on.

She quickly found the same symptoms elsewhere. In Coopersville, a former mining town now strangely dependent on elder care, Sunset Terrace recorded a severe resident fracture, dismissed internally as "unforeseeable." In Valeridge, amidst endless farm lots where the land was cheap and care homes bloomed, Coastal View Retirement saw a resident suffer acute dehydration. Three facilities, three distinct tragedies, and three identical, hollow conclusions: "No systemic fault." The pattern was the true crime.

Unmasking the Funding Failure

The negligence wasn't confined to one greedy corporation; Bobbi realised it was woven into the fabric of public policy. She broadened her focus to the central Health Funding Authority (HFA), the colossal public body that hands out contracts to private operators.

The problem lay in a chilling bureaucratic failure—a profound indifference to data accuracy that was costing lives.

The HFA was sharing only basic demographic data with contractors when drawing up service agreements. The contracts budgeted money for a theoretical patient who needed minimal help, entirely missing the true acuity of care (post-op needs, two-person transfers, severe dementia). The funding formulas, relying on this generalized, deficient information, were constantly falling short of the actual operational costs required to meet mandated safety standards.

Bobbi traveled to Cederville, once a prosperous logging hub, now a town where felled forests were replaced by new care home developments. She found that the contractors here—including several smaller, independent operators—also admitted to the Impossible Choice forced upon them by the HFA’s shortfall. They couldn't run the home at a profit while adhering to legal staffing levels. The system’s failure forced them to risk illegality simply to stay solvent.

The Full Picture - Can Compassion Kill?

Bobbi’s final exposé, published amidst the peak of the corporate defamation campaign, laid bare the Three-Point System Failure that caused Mr. Chen’s death and countless other tragedies:

The HFA's Failure: Providing insufficient and misleading data, creating an inadequate funding structure.

The Corporate Contractor's Failure: Willfully exploiting the funding shortfall by implementing a fraudulent, systemic understaffing policy to ensure profit.

The Regulatory Body's Failure: Failing to adequately audit or enforce standards, allowing the illegal cost-cutting to continue unchecked.

The investigation culminated in Vanderside, the great seaport city and corporate hub. Bobbi confronted the heads of the corporate chain and the HFA Director. They offered synchronized statements of "deep concern" and promises of "immediate internal review."

The Epilogue: Systemic Tokenism

The public outrage and subsequent coronors court, forced the political machine to act. They launched an "Independent Review" and promised reform.

Bobbi, however, saw the cynical reality: the changes were superficial. The HFA announced a "New Acuity Metrics Data System"—a superficial rebranding. The Regulatory Body promised "enhanced spot-check audits"—a few more visits easily managed by contractors who knew how to game the system.

This was systemic tokenism. The government performed an illusion of concern, launching a public relations campaign instead of actual structural reform. The regulatory fines increased, but the corporations simply absorbed the cost. The watchers—the HFA and the regulators—proved they were not blind, but willfully blind, prioritizing political stability and budget appeasement over human life.

Bobbi Ditchcroft, having risked her career, had shone a light on the gaps in the system. The system that killed Mr. Chen was still in place, just quieter and harder to prove.

The question that lingered, hanging over the cold, clear air, was the ultimate consequence of this institutional betrayal, and where is Bobbi now?

The Guiding Algorithm: How Health and Safety Becomes a Way of Life

As a young man, at the age of 11, life put me in a situation where I became the care aide for my family after it fell apart—a story I'm sure many of you can relate to. This isn't an appeal for sympathy, but rather an explanation for my choices. I had to learn to defend myself and my brother living in a working-class area, especially being from a different part of the country; we stood out like a sore thumb with our accents, talk about the north-south divide in the UK.

At 17, I joined the Royal Navy, under the naive illusion that serving my country was the best way to help my family—but hey, at least I tried, eh? I then invested my time in martial efficacy, not for the romance of swanning about with medals and such, but for a deeper understanding of violence and how to manage it. Fitness was my next goal, then nutrition, and finally, the last battlefield: the mind, specifically behaviour. All this as a layman, mind you, as finances held me back from more institutional pursuits.

Now that I find myself in a position with some top-notch "edumacashun," over the last several years, I aim to coalesce my boots-on-the-ground (sometimes, boots in my face) experience from the military, industry, law enforcement, and care sectors to give something back in the form of health and safety.

With all this global chatter going on in our personal algo’s, only those with a clear purpose can steer through it all, will benefit. We'll just have to wait for the rest to catch up. So strap in and buckle up for a critical mindset, squirrel thinking jaunt, into holistic H&S. If you dare!!

Health and safety is often seen as a dry, rule-bound subject, far removed from the dynamic flow of everyday life. But what if we reframed it? What if health and safety weren't just a checklist, but a powerful, principle-based algorithm for navigating the world, ensuring growth, adaptability, and minimal suffering? This article will explore how ancient wisdom, modern science, and practical experience converge to define health and safety as a fundamental way of being—a "guiding algorithm of life."

The core idea woven throughout this understanding is adaptability through being submaximal of the constant of change. This means consistently operating just below your absolute maximum capacity, allowing for continuous growth and resilience without burnout or breakdown. This principle, scalable from an individual's personal development to the governance of entire organisations, holds the key to thriving in an ever-changing world.

The Individual Blueprint: Submaximal Effort and Hardwired Adaptability

Our personal experiences shape how we see the world. Whether through the structured lens of engineering, the disciplined physical arts or happenstance, we develop filters that influence our responses to risk and change. It's within this individual context that the principle of being "submaximal of chaos" truly begins to shine.

Consider the world of functional fitness and anaerobic threshold training. Here, the goal isn't to constantly push to your absolute limit, but to train intensely enough to stimulate growth while leaving a small reserve. This "sweet spot" allows the body to adapt and recover more efficiently, leading to sustainable improvements in strength and resilience. This is a direct, physiological example of operating submaximally.

This physical training is deeply intertwined with our mental and emotional processing. Research by Dr. James Cahill from UCLA highlights how adrenaline acts as a powerful memory fixer. When we experience something with strong emotional significance, enough to change our physiology – even in a controlled training scenario – adrenaline helps to solidify that memory (and yes, it can be induced through exercise). This means that practising a safe behaviour in a realistic, slightly stressful environment can literally "hardwire" that response into our brains. It becomes an "artificial memory engram," as Jungian psychology might describe it, an ingrained pattern that can be accessed quickly and efficiently when needed.

This concept resonates strongly with behaviourism and the training methods found in martial arts. A martial artist doesn't just learn moves; they develop tactile awareness through countless repetitions. This practice, often performed submaximally, builds muscle memory and an intuitive understanding of movement and space. When faced with a real-time challenge, their body adapts almost instantly, acting without conscious thought. This cultivated, intuitive adaptability mirrors the principles of the UK's Health and Safety at Work Act 1974, which, as we'll see, emphasises proactive risk management and flexible responses over rigid rules.

From Individual Mastery to Systemic Governance

The principles that guide individual adaptability are perfectly scalable to larger groups, organisations, and even society itself. Effective leadership, whether in ancient battlefields or modern boardrooms, hinges on a deep understanding of human nature and the ability to foster adaptable systems.

Niccolò Machiavelli's The Prince, though controversial, offers a starkly pragmatic view of leadership. His insights into how people are motivated, especially by the potential of losing everything, underscore the importance of understanding human psychology in governance. While he suggests that fear can be a powerful motivator, our discussions also highlighted that sustained fear is not a convenient or effective way to inspire people long-term. Instead, it leads to resentment and stifles creativity. A truly robust system acknowledges human drives but seeks more sustainable forms of engagement.

This aligns with Miyamoto Musashi's wisdom in The Book of Five Rings, where he compares a general to a good carpenter. Just as a carpenter knows the strengths and weaknesses of his wood, a general must deeply understand his men – their capabilities, their morale, and how best to deploy them. This isn't about rigid control, but about leveraging individual strengths within a flexible, overarching strategy. It's an adaptable, principle-based approach to leadership.

When these individual and leadership principles are applied broadly, they create a robust organisational and societal structure. This can be visualised as a toroidal effect – a continuous, flowing system where information and feedback circulate freely, fostering constant adaptation and improvement. Such a system is not static; it's dynamic and self-correcting.

This model is clearly reflected in modern health and safety legislation. The ILO's mandate to remove human suffering provides the ethical compass, emphasising the accountability of those in leadership. This translates into laws like the UK Health and Safety at Work Act 1974, which is famously principle-based. It doesn't dictate every single action but requires employers to do what is "reasonably practicable" to ensure safety. This legal framework demands continuous risk assessment, review, and adaptive foresight—the skill of anticipating change and preparing flexible responses, rather than simply reacting to crises.

Health and Safety: The Guiding Algorithm of Life

In essence, health and safety, when understood through this holistic lens, transform into a universal guiding algorithm. It’s a philosophy that teaches us to embrace constant change by continually adapting just below the point of exhaustion. It's about developing internal resilience and external flexibility.

This guiding algorithm allows for minimal effort for the maximum effect whilst not bringing risk to the organism. It’s the wisdom to read the subtle signs of impending change ("the shark fin making a ripple"), to understand where pressure points exist, and to choose wisely whether to absorb, redirect, or dig in. It is the realisation that rigid policies fail, while principle-based adaptation allows for evolution. Like a river managed by adapting to its flow, not controlling it, life and all its systems flourish when they learn to navigate the constant currents of change.

Sources

Machiavelli, Niccolò. The Prince. c. 1513.

Musashi, Miyamoto. The Book of Five Rings. c. 1645.

Cahill, James. Research on the neurobiology of memory consolidation at the University of California, Irvine.

Health and Safety Executive (HSE). Health and Safety at Work etc. Act 1974.

International Labour Organisation (ILO). Constitution and Mandates.

NEBOSH. National Examination Board in Occupational Safety and Health.

Jung, Carl. Works on Analytical Psychology.

Kahneman, Daniel, and Tversky, Amos. Research on Prospect Theory and Loss Aversion.

A Shared Lineage: How the Right to Self-Determination Paves the Way for World-Class Safety

International Labour Organisation est 1919, Convention C155 (1981 H&S) - ISO 45001 Conventions 169 (1989 Tribal Peoples Convention) UNDRIP

In the world of international law and corporate governance, documents often seem siloed and distinct. Human rights declarations are one thing, and workplace safety standards are another. But for Indigenous Nations and forward-thinking consultants, a deeper connection reveals a powerful strategic opportunity. What if the principles behind a global safety standard like ISO 45001 were a natural and logical extension of the very rights affirmed in documents like UNDRIP and international labor conventions?

This is not a theoretical exercise; it's a profound strategic insight. When we trace the lineage of these international frameworks, a shared commitment to human dignity, participation, and self-determination becomes clear.

A Foundation of Participation and Consent

The most direct link between Indigenous rights and international labor standards is found in the ILO Indigenous and Tribal Peoples Convention, 1989 (No. 169). This legally binding treaty was a groundbreaking move away from paternalistic policies, establishing a framework of consultation, participation, and consent. It was the first major international agreement to affirm the right of Indigenous peoples to control their own development and maintain their own cultures and institutions.

The UN Declaration on the Rights of Indigenous Peoples (UNDRIP) takes these principles and expands upon them. It builds on the foundation laid by ILO C169, moving from "consultation" to the stronger standard of "free, prior, and informed consent" (FPIC). The drafters of UNDRIP, including extensive input from Indigenous peoples themselves, saw C169 as an essential starting point, a step towards a more complete and powerful affirmation of their rights.

The Broader Human Rights Echo in ISO 45001

While it may not be immediately obvious, the principles found in a safety convention like ILO Convention 155 (Occupational Safety and Health) are a clear echo of the rights affirmed in UNDRIP. They all spring from a shared international understanding that people have fundamental rights to safety and a say in their own well-being.

Worker Participation: ILO C155 emphasizes the importance of involving workers and their representatives in safety decisions. This mirrors UNDRIP's core principle of meaningful participation, where Indigenous peoples must be consulted on all matters that concern them.

The Right to a Safe Environment: C155 is based on the principle that every worker has a right to a safe and healthy work environment. This is a fundamental human right. UNDRIP, in a much broader sense, affirms the right of Indigenous peoples to a healthy and safe environment, which is crucial for their physical, cultural, and spiritual survival.

When seen through this lens, ISO 45001 becomes more than just a safety standard—it becomes a practical, internationally recognized tool for exercising these very rights. The ISO 45001 framework requires leadership commitment and active worker participation. It is not an imposed program, but a system that an organization—in this case, an Indigenous Nation—can build, own, and govern.

Seizing a Global Opportunity

In an increasingly complex world, Indigenous Nations are asserting their sovereignty and engaging with global partners. The Certificate of Recognition (CoR) program is a valuable and respected Canadian standard, but it is primarily a regional compliance tool. By adopting ISO 45001, a Nation can signal that it is not just meeting local requirements but is aligned with the highest standards of global excellence.

For leaders of Indigenous Nations, this is an opportunity to formalize principles of self-determination and community governance into a management system that protects your people, builds credibility with international partners, and opens new doors for economic development.

The profound lineage between international human rights and labor standards is a powerful story. By embracing a global standard like ISO 45001, a Nation doesn't just improve safety—it makes a strategic statement about its readiness to lead and succeed on its own terms.

What Are Toolbox Talks For? From the Battlefield to the Boardroom.

The "toolbox talk," a familiar term in construction and trades, is more than just a quick chat about safety. Its origins are speculative but rooted in a pragmatic need for on-the-job safety communication. This simple practice has evolved into a cornerstone of a concept known as High-Reliability Organizations (HROs), which are entities that operate in high-risk environments with a remarkable safety record. The principles of these briefings, used by the military and modern HROs, are becoming increasingly vital for small businesses in a rapidly changing world.

From Speculative Origins to Widespread Adoption

While the exact origin of the toolbox talk is debated, its etymology points to its function. It's a meeting held around the toolbox at the start of the workday, a brief, informal, and conversational way to discuss a specific safety issue or task. This simple practice became a key tool for WorkSafeBC and other regulatory bodies to promote workplace safety. WorkSafeBC, for example, emphasises the value of these talks in its resources, noting that they help to "identify and discuss hazards" and "reinforce safe work practices" on site, serving as a critical component of a company's overall safety program.

The concept of the toolbox talk as a brief, focused safety meeting is a fundamental principle of workplace health and safety. ISO 45001, the international standard for occupational health and safety management systems, stresses the importance of "consultation and participation of workers" in hazard identification and risk control. A toolbox talk is a practical, on-the-ground example of this principle in action, providing a platform for workers to contribute directly to their own safety. Similarly, the International Labour Organisation (ILO) Convention 155, concerning occupational safety and health, highlights the need for employers to "provide and maintain workplaces, machinery and equipment...without endangering the health of workers." A toolbox talk is a direct tool to communicate and reinforce these provisions.

From the Battlefield to the Boardroom: The Military and HROs

The practice of the "brief" is deeply ingrained in military culture. The Royal Navy, for instance, has long used a watch brief by the Duty Petty Officer to ensure a seamless and safe transition between watches. This briefing is not merely a transfer of responsibility but a comprehensive overview of the ship's status, any ongoing operations, and, critically, any potential hazards. As discussed in our chat, a similar practice exists in military operations and is a prime example of an HRO at work.

This is a key tenet of HROs like air traffic control and hospital operating rooms. In these environments, the transfer of situational awareness is paramount. The shift change report in a hospital and the position relief briefing in an air traffic control centre are highly structured, transparent, and meticulously recorded activities. These briefings ensure that every member of the new team has a complete and accurate mental picture of the current state of operations. This practice is driven by the HRO principle of preoccupation with failure, where the smallest sign of a problem is seen as a potential symptom of a larger, systemic issue. NEBOSH, a leading global provider of health and safety qualifications, teaches these exact principles, emphasising the need for effective communication, documentation, and a culture that values shared responsibility.

Why is this so Important for Small Businesses Today?

For a small business—be it an electrical company, a bakery, or a doctor's office—the need for these briefings has never been more pressing. Here's why:

1. The "Circle of Work" & New Employees: Small businesses are often fluid environments with high turnover or seasonal staff. New employees, or even those returning after a break, need to be brought up to speed quickly and safely. A formal, though brief, handover process ensures they are aware of the day's tasks, any specific hazards (like a new piece of equipment in the bakery or a patient with a unique medical history in a doctor’s office), and the proper procedures. This reduces the learning curve and, more importantly, prevents accidents caused by a lack of information. The ILO Recommendation 164 highlights that "provision should be made for suitable training arrangements...to ensure that workers have the necessary knowledge and experience." This is a direct parallel to the function of a toolbox talk.

2. Transparency & Accountability: In today's litigious environment, a lack of documented safety training can be a significant liability. Moving from a paper log to a digital tracking system, as modern HROs do, provides a clear, auditable trail. This digital record shows that the business has taken reasonable steps to ensure the safety of its workers, covering the topics discussed and who attended. The Canadian Centre for Occupational Health and Safety (CCOSH) also advocates for documentation, stating it is "important for showing that due diligence has been exercised in providing a safe and healthy workplace."

3. Proactive Risk Management: The core benefit of a toolbox talk or briefing is that it shifts the mindset from reactive to proactive. Instead of waiting for an incident to occur, businesses are encouraged to identify potential problems before they happen. For example, a hairdresser's morning brief can address a recent slip hazard or a new hair product, while a hardware store's briefing can highlight which power tools have had a recent recall. This is a form of collective mindfulness that is central to HROs and is easily adaptable to any small business.

In essence, whether it's on a nuclear submarine, a construction site, or in a veterinarian's office, the toolbox talk and its variants serve the same purpose: to ensure that a team is not just physically ready for the work ahead, but mentally and communally prepared to identify, mitigate, and respond to risk. It’s a simple, but profound, exercise in good leadership and collective responsibility.

References:

ILO C155 and R164: International Labour Organisation Conventions and Recommendations on Occupational Safety and Health.

CCOSH: Canadian Centre for Occupational Health and Safety.

WorksafeBC: The Workers' Compensation Board of British Columbia.

ISO 45001: International Organisation for Standardisation, Occupational health and safety management systems.

NEBOSH: National Examination Board in Occupational Safety and Health.

If you want to fail, ignore this business blueprint - Management of Change

Business success hinges on the ability to manage change. An integrated approach to change management is crucial for a business to thrive, as it directly links a company's health and safety performance to its financial and operational viability. Ignoring the management of change (MoC) is a surefire way to bleed profit and lose staff. It's a fundamental business blueprint, not just a health and safety add-on.

The Toroidal Effect

Think of a business as a dynamic system with a constant flow of data, much like a torus or a doughnut shape, where data circulates and influences the entire system. In this toroidal effect, leading and lagging data continuously feed into the system. Leading data, which is proactive, looks at things like training completion, hazard identification, and planned safety observations. It's the equivalent of a weather forecast, allowing you to prepare for potential storms on the horizon. Lagging data, on the other hand, is reactive. It includes incident rates, lost-time injuries, and audit findings. It tells you what has already happened, serving as a feedback loop for what went wrong.

These two types of data work together in a continuous cycle:

Leading data informs your proactive planning and risk assessments.

Near misses, changes in operations, leadership, or purchases trigger internal audits.

Lagging data from these audits and incidents reveals gaps in your processes.

This audit data is used to upgrade your management system, which in turn influences your leading data and proactive measures, completing the loop.

This cycle, fueled by both leading and lagging data, is how a business continuously adapts and improves.

Your Business Plan is Your Health and Safety Plan

Leading organisations like WorkSafeBC and the HSE UK emphasise that effective health and safety management is not separate from a business's overall strategy. In fact, they are the same. A business plan is a roadmap for success, and a health and safety plan provides the guardrails to ensure that journey doesn't lead to a dead end.

A proactive approach, often called "due diligence," means you take every reasonable precaution to protect your people and assets. Ignoring a near miss is like ignoring a velociraptor testing the perimeter in Jurassic Park or the shark's fin in Jaws; it's a signpost of a future disaster. WorkSafeBC, for example, highlights that leadership commitment is the first step toward building a strong safety culture. It starts at the top, with leaders demonstrating that they value worker well-being.

Objectives and Key Results (OKRs) and SMART Goals

To navigate this blueprint for change, businesses need clear goals and metrics. This is where OKRs (Objectives and Key Results) and SMART (Specific, Measurable, Achievable, Relevant, Time-bound) goals become crucial.

OKRs set an overarching objective (what you want to achieve) and a few key results (how you will measure progress). For example: Objective: Improve workplace safety culture. Key Results: 1) Reduce near misses by 25%. 2) Increase proactive hazard reporting by 50%.

SMART goals provide a framework for achieving these key results. They are specific, actionable targets. For example: Goal: All employees will complete the new online safety training module by October 31.

These goals directly influence KPIs (Key Performance Indicators), which track and measure the success of your business. When an organisation sets an OKR to reduce incidents, it drives the creation of SMART goals for training and risk assessments. This proactive work, in turn, directly impacts your KPIs, such as a reduced incident rate or improved productivity.

The MoC Blueprint

The Management of Change (MoC) is a core principle endorsed by organisations like NEBOSH and the HSE. It provides a structured process for handling changes to equipment, processes, and personnel. The blueprint for MoC includes:

Planning: All changes must be planned and assessed.

Risk Assessment: A thorough risk assessment must be performed to identify potential new hazards.

Mitigation: Steps must be taken to mitigate identified risks.

Training: Workers must be trained on the new procedures.

Approval: Management must approve the change at key stages to ensure all safety aspects are considered.

This blueprint is supported by international standards like ISO 45001 (Occupational Health and Safety), which provides a framework for managing risks and improving performance. As the British Safety Council notes, these standards recognize that a change in one area—say, introducing a new piece of equipment—can have a ripple effect on safety, quality, and the environment.

By adopting this integrated and proactive approach to change, a business can transform challenges into opportunities for growth and continuous improvement. It's a principle-based approach that ensures adaptability is not a submaximal form of chaos but a planned and measurable path to success.

Sources:

British Safety Council. (2025). Changes to ISO management standards: start preparing now.

WorkSafeBC. (n.d.). Enhancing health & safety culture & performance.

The Chemical Institute of Canada. (n.d.). Managing the Health and Safety Impacts of Organisational Change.

NEBOSH. (2020). NEBOSH achieves ISO 45001.

NEBOSH. (n.d.). Management teams must lead by example and practice what they preach.

4 Simple Steps to Create a Safety Policy for Your Team

Working in British Columbia, everyone has a part to play in keeping the workplace safe. A strong safety policy is like a rulebook that helps a team prevent injuries and stay healthy. It’s not just a good idea—it’s a legal requirement in our province, and it's a way for a company to show that it truly cares about its people.

Creating a safety policy might seem like a big job, but it can be broken down into a few simple steps. This guide will help you understand what needs to be in a great safety policy, using ideas and rules from B.C.’s laws and safety organizations like WorkSafeBC and CCOSH (the Canadian Centre for Occupational Health and Safety).

Step 1: Understand Why It's a Must-Do

First, it’s important to know that having a safety policy isn’t optional. According to B.C.'s Workers Compensation Act and the Occupational Health and Safety (OHS) Regulation, all workplaces must have a health and safety program. For many, especially larger teams, this includes a written safety policy. Think of it as a clear promise from the employer that they will do everything they can to keep you safe.

This is where the law gives everyone a clear role:

Employers are responsible for providing a safe workplace, training workers, and making sure the rules are followed.

Supervisors must ensure workers are following safety procedures and are trained to do their jobs safely.

Workers also have a responsibility to follow the rules, report hazards, and use safety equipment correctly.

WorkSafeBC's rules also include a very important right for all workers: the right to refuse unsafe work. If you have a good reason to believe a task is dangerous, you have the right to refuse it until the risk is investigated and fixed. A good safety policy will clearly explain this right and the steps to follow if a situation like this happens.

Step 2: Make It Personal (and Official!)

The best safety policies aren't just a copy-and-paste from another company. They are designed specifically for your workplace and the unique risks you face. A warehouse will have different safety needs than a hair salon or a construction site.

To get started, consider what CCOSH recommends:

Show Your Commitment: The policy must be a real promise from the top. It should be signed by the most senior person in the company, like the owner or a manager. This shows everyone that safety isn't just a small detail—it's a top priority.

Team Up to Write It: A safety policy is much more effective if it's created with input from the people who work there every day. Involve supervisors, workers, and, if your workplace has one, the joint health and safety committee. This collaboration helps find hidden dangers and creates a policy that everyone believes in and will actually follow.

Keep It Clear and Simple: Avoid complicated language. The policy should be easy for everyone to read and understand, no matter their background. It should explain the rules and responsibilities in a way that makes sense.

Step 3: What to Put in Your Policy

A good safety policy isn't just a list of rules; it's a plan for action. It should clearly explain how your team will handle different situations. Here are some key things to include:

A Safety Statement: A short paragraph that says, "We are committed to providing a healthy and safe workplace." This sets the tone for the entire document.

Roles and Responsibilities: Clearly state what is expected of the employer, supervisors, and workers. For example, the policy might state that "Supervisors are responsible for training new workers on safe procedures," and "Workers are responsible for reporting any injuries or hazards right away."

How to Handle Hazards: Your policy should explain how to identify, report, and fix dangers in the workplace. This includes both physical hazards (like a slippery floor or a broken ladder) and mental or emotional hazards (like violence or bullying).

Emergency Plans: What should the team do if there is a fire, a medical emergency, or a natural disaster? Your policy should have clear procedures for how to react. This includes having a plan for things like first aid, evacuations, and calling for help.

Training and Education: The policy should describe how new team members will be trained on safety rules. It should also explain how everyone will get refreshers or new training when needed, such as when new equipment is introduced.

Incident Reporting: Explain how and when to report an accident, injury, or near-miss. This is crucial because it helps the company learn from what happened and prevent it from happening again.

Step 4: Keep It Alive

A safety policy isn't a document you write once and then forget about. It needs to be a living, breathing part of your workplace.

Communicate It: Make sure every single team member knows about the policy. Post it in a visible place, include it in new worker orientation, and talk about it at safety meetings. The policy is only effective if people know what it says.

Review and Update: The workplace changes over time. New tools are used, new jobs are created, and new risks appear. It's a good practice to review your safety policy at least once a year, or whenever something significant changes, to make sure it's still accurate and useful. WorkSafeBC and CCOSH both recommend regular reviews to keep the policy up to date.

Creating a safety policy isn’t just about following the law; it's about building a culture where everyone looks out for each other. By taking these simple steps, you can build a safety program that not only meets legal requirements but also protects your most valuable asset: your team.

My H&S Spirit Animal is a Squirrel Piloting a Flying Corkscrew in a Tornado

When I consider the ideal mindset for a health and safety professional, I don't envision a perfectly organized spreadsheet or a rigid, linear checklist. Instead, my mind conjures a more chaotic yet oddly effective image: a squirrel at the helm of a flying corkscrew, deftly navigating the winds of a tornado.

This image, as peculiar as it is, embodies three essential cognitive processes: "squirrel thinking," pattern recognition, and critical thinking. Separately, they are useful skills. Combined, they form a powerful approach to risk management and problem-solving.

The Power of "Squirrel Thinking"

"Squirrel thinking" is not about being scatterbrained; it's about being relentlessly curious and drawing connections from a wide-ranging, diverse knowledge base. It's the ability to dart from one seemingly unrelated subject to another—from historical treaties to behavioral psychology, from engineering principles to storytelling—and collect valuable insights along the way.

This non-linear approach is crucial for innovation. A specialist in one field might miss a solution because their focus is too narrow. The "squirrel thinker" brings a broader perspective, finding solutions by borrowing concepts from different disciplines. For example, understanding operant conditioning, a concept championed by B.F. Skinner, allows a safety professional to recognize that workers repeat unsafe behaviors (the "squirrel's path of least resistance") because of subtle, positive reinforcement (e.g., completing a task faster). The squirrel thinker can then design a safety program that focuses on reinforcing safe behavior instead of just punishing unsafe acts.

The Foundation of Pattern Recognition

At the heart of "squirrel thinking" is a refined sense of pattern recognition. This is the fundamental ability to perceive order in chaos—to see the repeating motifs in data, events, or behaviors. In a tornado of information, the squirrel's corkscrew path isn't random; it's a search for familiar shapes and recurring risks.

This concept is supported by the work of cognitive neuroscientist Irving Biederman, who proposed that the human brain recognizes objects by breaking them down into basic geometric shapes called "geons." We can extend this idea to safety: the chaos of an incident is a collection of complex, interconnected details. The skilled professional breaks down the event into its fundamental "geons"—the unsafe acts, the system failures, the environmental factors—and can then recognize how these basic components have appeared in past incidents. This allows for proactive intervention before a new tragedy occurs.

The Anchor of Critical Thinking

Without a counterbalance, "squirrel thinking" can lead to chaos. This is where critical thinking acts as the anchor. It’s the logical, disciplined process that evaluates the patterns and ideas found by the squirrel.

The goal is to temper the "random" with a rigorous, systematic evaluation. This requires a psychologically safe environment, a concept championed by Amy Edmondson. She defines psychological safety as a shared belief that a team is safe for interpersonal risk-taking. In this context, a worker or a professional can share a "squirrelly" idea or a strange observation without fear of ridicule. An employee can say, "Something about this process reminds me of a game of chess, and I'm worried we're missing the endgame," and have that observation taken seriously. Critical thinking then takes over to analyze and validate the observation, turning an intuitive leap into a concrete strategy.

The Synthesis

In the end, the most effective approach to health and safety is a dynamic synthesis of these three elements. It's the "squirrel" that intuitively gathers disparate information and sees the potential connections; it’s the pattern recognition that sifts through the data for recognizable trends; and it's critical thinking that applies a logical, evidence-based lens to confirm, refine, and act upon those insights.

The health and safety professional is not a linear thinker. They are a multi-faceted problem-solver who can embrace the chaos of "squirrel thinking," rely on the foundational skill of pattern recognition, and use critical thinking to pilot their way to a safer future for everyone.

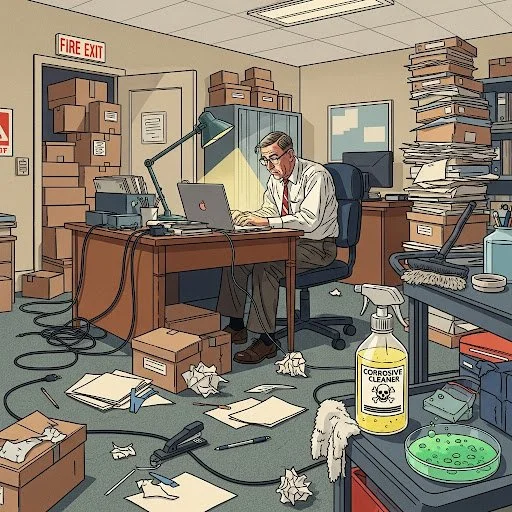

5 Common Health and Safety Hazards in Small Offices (and How to Fix Them)

It's easy to think of health and safety as a concern only for construction sites or factories. But even in professional settings like law firms, medical offices, and care homes, common hazards can lead to serious injuries, fines, and operational disruptions. As your local health and safety gurus at Active8-HSS, we've identified the top five hazards we encounter in Cranbrook offices and what you can do to fix them.

1. Slips, Trips, and Falls

This is the most common workplace injury across all sectors, and small offices are no exception. The culprits are often seemingly harmless: cluttered walkways, loose cords, wet floors near entrances, or uneven rugs. In a busy clinic or care home, spills and equipment left in a hurry can pose a significant risk to both staff and clients.

How to Fix It:

Maintain Clear Pathways: Regularly check for and remove clutter from aisles and walkways. Ensure all boxes, files, and equipment are stored properly.

Manage Cords: Use cable covers or ties to bundle and secure electrical and networking cords. Keep them tucked away from foot traffic.

Immediate Clean-Up: Implement a "see something, say something, clean it up" policy for spills. Have a designated area with wet floor signs and cleaning supplies.

2. Ergonomic Injuries

For professions that involve long hours at a desk (lawyers, administrative staff) or repetitive tasks (dentists, vets), poor ergonomics can lead to musculoskeletal disorders. These are chronic and debilitating injuries affecting the back, neck, wrists, and shoulders, and they can severely impact productivity and quality of life.

How to Fix It:

Proper Equipment: Provide adjustable chairs, ergonomic keyboards, and mousepads. Ensure computer monitors are at eye level to prevent neck strain.

Assess Workstations: Conduct a simple ergonomic assessment for each employee. Active8-HSS can help you identify and correct poor posture and setup.

Encourage Breaks: Remind staff to take regular short breaks to stretch and move around. A simple five-minute break every hour can make a huge difference.

3. Biological and Chemical Hazards

This hazard is particularly relevant for medical, dental, and veterinary offices. Workers can be exposed to bloodborne pathogens, infectious diseases from patients or animals, and hazardous chemicals used for cleaning, sterilisation, or anaesthesia. In care homes, handling bodily fluids and cleaning agents requires strict protocols.

How to Fix It:

Infection Control Plan: Develop and enforce a detailed infection prevention and control (IPAC) program. This should include procedures for hand hygiene, surface disinfection, and sharps disposal.

Personal Protective Equipment (PPE): Ensure all staff have and properly use the required PPE, such as gloves, masks, gowns, and face shields.

Hazard Communication: Clearly label all chemical containers and provide staff with proper training on handling, storage, and emergency procedures (e.g., a spill kit).

4. Fire and Electrical Hazards

Overloaded outlets, frayed cords, and improper use of space heaters are silent but deadly threats. Small offices, especially in older buildings, may have outdated electrical systems that cannot handle modern equipment, increasing the risk of electrical fires.

How to Fix It:

Electrical Inspections: Have a qualified electrician inspect your office's wiring. Avoid using extension cords as a permanent solution.

Educate Employees: Train staff to recognize and report damaged equipment, overloaded circuits, and unsafe use of personal appliances.

Fire Safety Plan: Ensure you have working smoke detectors, fire extinguishers in accessible locations, and a clear, well-communicated fire evacuation plan. Conduct regular fire drills to ensure everyone knows the procedure.

5. Workplace Violence and Security

While often overlooked, the risk of violence from clients or patients is a real concern for all offices, particularly those in healthcare and legal services. This can range from verbal abuse to physical assault. In a care home, staff must be prepared to handle aggressive behaviour from residents.

How to Fix It:

Create a Policy: Develop a clear policy on workplace violence and harassment that includes procedures for reporting incidents and de-escalating situations.

Staff Training: Provide staff with training on conflict resolution, de-escalation techniques, and how to handle difficult individuals safely.

Physical Security: Implement measures such as panic buttons, secure entryways, and adequate lighting to enhance staff safety, particularly during off-hours.

Need Help? We're Your Local Guros.

Tackling these hazards can seem overwhelming for a busy small business owner. But it doesn't have to be. Active8-HSS specializes in helping businesses like yours build simple, effective health and safety programs that protect your team and your bottom line. We can conduct a full hazard assessment, create a customized safety plan, and provide the training you need to stay compliant and safe.

Don't wait for an accident to happen. Protect your people and your business today.

The HR Purgatory: A Glitch in Quality Control, waiting for a job reply?

An Exclusive Interview by an Investigative Journalist Stanley Morton.

I sat across from Dr. Alistair Felix, a man whose career spanned theoretical physics and Jungian philosophy. Beside him was Father Thomas, a Jesuit priest known for his work in both theology and digital ethics. We were in a small, sterile conference room—a liminal space in its own right—to discuss a discovery they claimed was both groundbreaking and deeply unsettling.

"The modern job application process," Dr. Felix began, "is a series of thresholds. You submit your resume, you wait. You get a reply, if you're lucky, by email. Then you wait, so you call and speak to a gatekeeper and are told, Sorry, the manager is in a meeting or has just popped out, would you like to leave a message? You do so as you have been told that showing your initiative is a good idea. But what we've observed is that for many, this process has ceased to be linear. It's a loop. A feedback cycle where the applicant is always in a state of 'almost there' but never arrives."

"We call it the HR Purgatory," Father Thomas added softly. "It's a state of being in which the soul, or in this case, the applicant's professional identity, is suspended between their old job and the promise of a new one. They are neither employed nor rejected, but perpetually in transition."

I asked them what led to this discovery.

Dr. Felix pulled up a complex diagram on a large screen. "We started by analysing the algorithms used by major HR platforms. They're designed to filter, to create a pipeline. But we found a subtle, yet significant, flaw. The algorithms are so optimised for efficiency that they've created a probabilistic cul-de-sac. They identify strong candidates but, through a series of automated filters and delays, fail to push them to the final stage. The system simply... forgets about them."

"From a theological perspective," Father Thomas explained, "it's a digital echo of Purgatory that has manifested itself in the liminal vacuum unintentionally created. Algorithms for coding could be argued as technosigils, used to create energy from the void. The system is designed to purify the applicant pool, but it has inadvertently created a holding pattern for those who aren't quite 'pure' enough to be hired, but aren't 'sinful' enough to be rejected. They are left in a state of longing, a painful limbo of hope and despair."

"The most intriguing part," Dr. Felix interjected, "is that the people operating these systems—the HR managers, the recruiters—are often unaware of this. They are simply following the process dictated by the algorithm. The system itself is the agent of this liminality, not the individuals."

I felt a chill. The HR Purgatory wasn't a deliberate act of cruelty, but a bug in the machine—an accidental metaphysical prison.

The question hung in the air: "So, what's the solution?" Dr. Felix and Father Thomas had exposed the problem, a digital purgatory for job applicants, but the cure seemed as elusive as a ghosted job offer. As I prepared to wrap up my interview, Father Thomas leaned forward, a new light in his eyes.

"We have a solution," he said quietly, "or rather, a counter-algorithm. Not a patch for the code, but a framework for human action. It's a return to first principles, to a documented and intentional process."

Dr. Felix nodded, pulling up a new diagram. This one was far simpler, a clean, linear flowchart. "We started by looking at an old framework for quality control," he explained. "It's a standard that companies use to ensure their products are consistent and reliable—ISO 9001. It’s based on a simple but profound idea: you must define your process, execute it, and provide evidence that you did."

"The algorithm for HR Purgatory fails at this fundamental level," Father Thomas interjected. "It's an opaque system that doesn't document its actions, leading to the spiritual limbo we've been discussing. Our counter-algorithm is a theological and technical application of ISO 9001's core tenets."

The priest and the physicist had collaborated to create a new set of principles, which they called The Competence and Conscience Framework:

1. Defined Thresholds (ISO 9001 Clause 7.2): "Every stage of the hiring process, every threshold the applicant crosses, must be clearly defined," Dr. Felix explained. "The system must have documented criteria for moving to the next step, or for a respectful, timely rejection. No 'probabilistic cul-de-sacs.'" The HR process was to be treated like a manufacturing line, where each "part" (the applicant) is either processed to the next stage or responsibly removed from the line.

2. Acknowledge All Souls (ISO 9001 Clause 7.3): "The first step of our counter-algorithm is an automated, but personalised, acknowledgement of every applicant," Father Thomas said. "It's a simple act of respect, a recognition of their existence. It's an act of awareness—the applicant knows their application has been received, and the company is aware of their submission. This closes the potential for a vacuum of hope."

3. The Doctrine of Accountability (ISO 9001 Clause 7.5): "The core of the counter-algorithm is a new module that we call the 'Feedback Loop of Record'," Dr. Felix said, his voice gaining momentum. "This module ensures that every single applicant receives a final communication, whether it's an offer, a request for more information, or a firm rejection. This communication is automatically logged in a way that is auditable, both for ISO 9001 compliance and for moral accountability." This created a digital paper trail, a record that would prevent any applicant from simply "disappearing" from the system.

"The key," Father Thomas concluded, "is that this isn't about simply being polite. It’s about building a system that treats every person with dignity. It's about recognising that the competence of a company—its ability to build a quality product or service—is directly tied to the ethical quality of its processes. The HR Purgatory was a glitch of the machine. The counter-algorithm is an act of human conscience, built on a foundation of quality and respect. Furthermore, it will echo in the community. People will talk about the way they were treated. In this day and age, it won't matter how much you spend on advertising if your reputation is burnt"

I left the conference room with a feeling of cautious optimism. The HR Purgatory was a very real, very modern problem. But perhaps the solution wasn't a complex, futuristic patch, but rather a return to an old, simple idea: that every process, every system, every technosigil, must have a heart.

15 Years to Build, 15 minutes to Lose: The High Cost of Neglecting Health, Safety, and Quality Control

In the bustling world of a small business, where every dollar and every minute counts, it can be tempting to view health and safety protocols as a burdensome expense. They're often seen as an obstacle to efficiency, a stack of regulations to comply with, rather than a core component of a company's success. However, neglecting workplace safety is not a cost-saving measure — it is an enormous and often hidden financial risk that can erode a company's most valuable asset: its reputation.

For small businesses, reputation in a close-knit community is the lifeblood of their success. It’s what builds trust, attracts new customers through word-of-mouth, and retains loyal employees. A strong reputation is like a reservoir of good faith, built up over years of hard work. But a single health and safety failure can be a crack in that dam, leading to a flood of negative consequences that are difficult to contain.

The International Labour Organization (ILO) provides stark figures that underscore the immense cost of poor health and safety. According to the ILO, the financial burden of workplace accidents and illnesses is staggering, costing the global economy approximately 4% of its annual Gross Domestic Product (GDP). This isn't just a macroeconomic issue; it's a direct threat to the bottom line of every business, regardless of size.

While the direct costs of an incident—such as medical expenses, fines, and legal fees—are significant, they are often overshadowed by the hidden, or indirect, costs. These can include:

Loss of Productivity: An injury to a key employee can halt production, disrupt operations, and require costly retraining for a temporary or permanent replacement.

Low Employee Morale: When employees feel unsafe, morale plummets. This can lead to increased absenteeism, higher turnover rates, and a decline in the quality of work.

Damage to Reputation and Brand Image: This is where a small business is most vulnerable. A single incident can become a viral news story within a local community. What took years to build can be lost in a matter of days.

Increased Insurance Premiums: A poor safety record will directly impact a company's insurance rates, locking in higher operating costs for years to come.

These indirect costs, according to some studies, can be two to three times greater than the direct costs, making a seemingly minor incident a catastrophic financial event.

The emotional and physical toll on a person who is injured on the job is, of course, immeasurable. The ILO reports that over 2.9 million workers die each year from work-related diseases or accidents, and hundreds of millions more suffer non-fatal injuries. For a small business, a single injury is not just a statistic—it is a personal tragedy that can deeply affect the entire community.

Once a company's reputation is damaged, the path to recovery is a long and arduous one. While there's no single statistic from the ILO on how long it takes to recover, market research shows that reputational damage can last for months, and in the case of a major incident, the effects can linger for years. The process requires a complete shift in mindset, a proactive approach to change, and a transparent commitment to rebuilding trust.

To restore a tarnished reputation, a business must do more than just apologize; it must demonstrate tangible change. This means:

Acknowledging the mistake and taking full responsibility.

Implementing robust health and safety measures and communicating them openly.

Re-engaging with the community to show a genuine commitment to their well-being.

The lesson for every small business is clear: investing in a proactive, preventative health and safety program is not an option; it's a strategic necessity. It's the most effective way to protect your employees, secure your finances, and preserve the reputation that you have worked so hard to build. In the end, good health and safety isn't a cost—it's the best insurance policy a small business can buy.

Beyond Tidiness: Why Housekeeping is the Cornerstone of Safety

In any setting, from the most intimate personal spaces to the vast, complex operations of global industry, there's a principle so fundamental to well-being that it often goes unnoticed: good housekeeping. It’s far more than just tidiness; it’s the bedrock upon which effective health and safety practices are built. Without diligent housekeeping, even the most advanced safety protocols can crumble, leaving individuals vulnerable to preventable harm.

Consider the enormous scale of the challenge. The International Labour Organisation (ILO) estimates that a staggering 395 million non-fatal work injuries happen worldwide each year.

While it’s difficult for global bodies to pinpoint an exact number directly attributable to "poor housekeeping" as a standalone category, its influence is undeniable and pervasive. The ILO highlights that slips, trips, and falls are among the most common causes of workplace injuries, and it explicitly states that many of these are a direct result of inadequate housekeeping – wet or contaminated floors, cluttered pathways, and improper storage. The difficulty in isolating "poor housekeeping" as a single cause stems from its insidious nature. Its effects often manifest as other types of accidents.

An obstructed pathway, a clear sign of poor housekeeping, might lead to a fall from height, or an incorrectly stored tool could result in contact with machinery. These incidents are then categorised by their immediate cause, rather than the underlying housekeeping deficiency that initiated the chain of events. Furthermore, the global aggregation of data, with varying definitions and collection methods across different regions, makes it challenging to draw a precise, globally consistent figure for housekeeping-related incidents. Despite these statistical complexities, the message is clear: poor housekeeping is a major contributing factor to a vast number of injuries annually.

It creates an environment ripe for accidents. Imagine any operational setting where tools are left haphazardly, materials are piled unsafely, or spills are not promptly addressed. This isn't just an untidy scene; it’s a landscape of hazards waiting for an incident to occur. A missed step, a bumped knee, or a more serious fall could be the immediate consequence, leading to personal suffering, lost time, and broader disruptions. The importance of housekeeping extends beyond preventing physical injuries. It is a multi-faceted discipline addressing a wide spectrum of potential harms. For instance, fire safety is intrinsically linked to organisational habits. Accumulations of easily combustible materials – be they discarded packaging, forgotten documents, or soiled rags – create fuel for potential blazes. Regular removal and proper storage of such items are fundamental principles of good housekeeping that significantly reduce fire risks.

Similarly, controlling exposure to hazardous substances relies heavily on consistent cleanliness. Regularly wiping down surfaces minimises chemical residue and airborne dust, thereby improving overall air quality and reducing the risk of respiratory issues or skin irritations.

Proper storage, labelling, and disposal of all substances, including chemicals, are also crucial housekeeping functions that prevent accidental contact or environmental contamination. Crucially, good housekeeping fosters a proactive safety culture. In clean and organised spaces, hazards are far more visible. A frayed electrical cord, a blocked emergency exit, or a malfunctioning piece of equipment stands out immediately against a backdrop of order. This heightened visibility enables swift action, transforming potential incidents into non-events. It empowers everyone to take responsibility for their surroundings, cultivating a mindset of vigilance and immediate correction.

This level of meticulous attention to detail and a proactive approach to safety is particularly characteristic of High Reliability Organisations (HROs). These are entities that operate in high-risk environments but manage to maintain remarkably low accident rates. A core principle of HROs is their relentless pursuit of error detection and correction, often before errors can escalate into catastrophic failures.

Good housekeeping aligns perfectly with this ethos. It's not just about cleaning up after a mess; it's about anticipating where messes might occur, understanding their potential consequences, and putting systems in place to prevent them or address them immediately. For an HRO, a cluttered aisle isn't just an untidy space; it's a potential weak link in their safety chain, a signal that diligence may be wavering. Their commitment to safety extends to every seemingly small detail, making impeccable housekeeping an integral part of their operational excellence and hazard prevention strategy.

Ultimately, housekeeping is not a one-time task but an ongoing commitment. It demands continuous effort and the active participation of every individual within a given environment. From implementing clear, designated storage zones and ensuring regular waste removal to maintaining equipment and promptly addressing spills, each seemingly minor act of housekeeping contributes to a larger, robust framework of safety. It's about embedding a mindset where vigilance for potential hazards becomes second nature to everyone.

While it may lack the dramatic urgency of emergency response or the complex engineering of advanced safety systems, housekeeping remains the quiet, indispensable backbone of health and safety. It is the Consistent, diligent effort that detects potential problems early, prevents escalation, and ensures that every operational setting remains a safe and healthy environment. By fully understanding its fundamental importance and adopting the meticulousness of High Reliability Organisations, we raise housekeeping from a mere task to the vital foundation it truly is for safeguarding well-being everywhere.

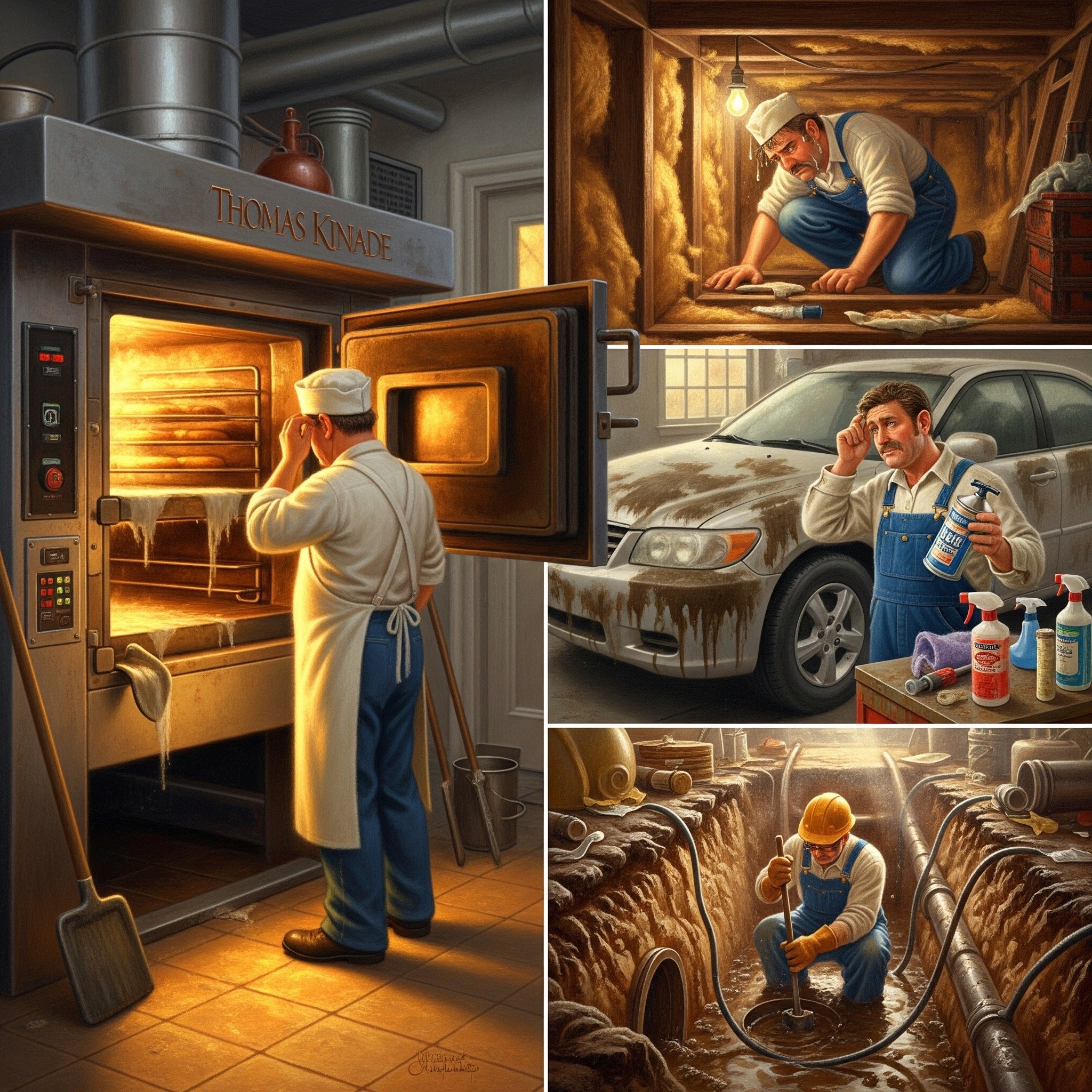

Unseen Dangers: Why Small Businesses Can't Afford to Be "Risk Blind" to Confined Spaces

In the world of occupational health and safety, the term "confined space" often conjures images of deep, industrial-scale environments—sewers, massive storage tanks, or underground mines. These are the classic, high-risk scenarios that major corporations with dedicated safety departments are well-versed in handling. However, this narrow perception has created a dangerous blind spot for small businesses, many of which are unknowingly putting their employees at risk by failing to recognize the confined spaces that exist in their own operations. This "risk blindness" is a pervasive and perilous issue, leading to a disproportionate number of preventable injuries and deaths in Canada each year.

The core of the problem lies in a failure to perform a proper risk assessment and apply a standardized definition. A confined space is not defined by its industry, but by three simple criteria: it's large enough for a person to enter and work, has a limited or restricted means of entry and exit, and is not designed for continuous human occupancy. When small business owners, from bakers to contractors, look past the obvious and apply this definition to their unique work environments, the reality of the risk becomes startlingly clear.

Consider the neighborhood bakery, a pillar of the community. The owner, focused on fresh-baked goods and customer service, may never have considered that a task as routine as cleaning the oven could be a life-or-death situation. Yet, a large commercial oven meets all the criteria of a confined space. If an employee must physically climb inside to scrub away residue, they are entering a space with a single, limited exit. The danger is compounded by the use of potent cleaning chemicals in this enclosed environment, which can rapidly create a hazardous atmosphere. Without a proper risk assessment, ventilation, and a documented entry plan, what seems like a simple chore becomes an incredibly dangerous undertaking.

Similarly, a small construction company might be working on a residential project, believing they are operating in a low-risk environment. But a crew member tasked with laying piping in a utility vault, a storm drain, or even a deep trench is entering a confined space. These spaces often contain hidden dangers like explosive gases, a lack of oxygen, or the potential for engulfment by collapsing soil. Small businesses, particularly those operating on a tight budget, may skip the crucial step of air quality testing, continuous monitoring, and having a dedicated attendant outside the space. This is a gamble with their employees' lives—a gamble they don’t even know they're taking.

While a car detailer might not be dealing with a traditional confined space—a car's interior allows for easy entry and exit—they are not without their own hazards. The use of powerful chemicals in a small, enclosed area can quickly create an unhealthy atmosphere. The lesson here is that even when a space doesn't fit the confined space definition, the principles of risk assessment still apply. Proper ventilation, personal protective equipment, and a clear understanding of chemical hazards are non-negotiable, and a risk-blind attitude towards these issues can lead to acute respiratory problems or other serious health effects.

The human cost of this risk blindness is staggering. Statistics from Canadian safety organizations reveal the brutal reality: over 100 people die in confined spaces in Canada every year, with the vast majority of these deaths resulting from an atmospheric hazard. What’s even more tragic is that a significant percentage of these fatalities are among would-be rescuers—colleagues who, in a moment of panic and without proper training, attempt to save a stricken worker and become a victim themselves. From 2011 to 2015 alone, there were nearly 12,000 lost-time injuries, a number that speaks volumes about the frequency and severity of these incidents.

These statistics underscore the vital importance of proper confined space training and a thorough risk assessment. For small businesses, this isn't about bureaucracy; it's about survival—both for the business and for its employees. Adopting a proactive safety culture, where every work environment is analyzed for its potential risks, is the only way to prevent these tragedies. The danger isn't always in a deep mine or a massive tank; sometimes, it's just a few feet away, hidden in plain sight, waiting for a business to become risk blind.

Your Small Business Team: Why a "Shamrock" Plan Is Smart for Rural Success

Starting a business in a small town or rural area is exciting! You have big ideas, but perhaps not a large budget or a massive team right from the start. So, how can you build your team efficiently and safely as you grow?

Ignore trying to create a huge, traditional company pyramid from day one. Instead, think of your business team like a shamrock – that lucky three-leaf clover! This clever approach, called the "Shamrock Organisation," helps small enterprises, especially in rural regions, to get things done without overspending. And guess what? You can combine it with a simple "pyramid" idea to make it even more effective.

What's the Shamrock Idea?

Think of your business as having three main groups of people, like the three leaves of a shamrock:

The "Core" Crew (Your Main Leaf):

Who they are: This is your small, super-important team. Maybe it's just you, or you and a co-founder, or a few key employees. These are the people who handle the main, special things your business does – what makes you unique! If you run a bakery, this is the head baker and manager. If you're a tech startup, it's your lead programmers.

Why they're great: They are dedicated, know your business inside and out, and are responsible for making the big decisions.

The "Hired Help" (Your Second Leaf):

Who they are: These are experts you bring in only when you need them. Think of them as contractors or freelancers.

Why they're great: Need a fancy website? Hire a web designer for that project. Need legal advice for a contract? Call a lawyer. Don't want to hire a full-time accountant? Pay one to do your books once a month. This saves you money because you only pay for their skills when you use them, and you don't have to cover their benefits or office space all the time. This is super handy in rural areas where finding specific full-time talent can be tough.

The "As-Needed" Crew (Your Third Leaf):

Who they are: These are part-time staff or temporary workers you bring in when things get busy.

Why they're great: If you run a seasonal business, like a busy farm stand in summer or a ski shop in winter, you can hire extra hands just for those busy times. When things slow down, you don't have a big payroll. This gives you amazing flexibility.

Mixing the Shamrock with a Simple "Pyramid"

Now, where does the "pyramid" come in? Even with a small shamrock team, it's wise to have a straightforward way of knowing who's in charge of what.

Imagine a very flat pyramid. At the top is you (the owner/manager). Below you are your "Core" crew, each responsible for their main area (like the head of sales or operations).

Example:

You (Owner/Manager) - Top of the Pyramid

Core Team:

Head Baker (responsible for making the bread)

Shop Manager (responsible for the daily running of the store)

Hired Help (Shamrock Leaf 2):

Local accountant (visits once a month)

Freelance designer (when you need new flyers)

Electrician (when something breaks)

As-Needed Crew (Shamrock Leaf 3):

Part-time counter staff (for busy lunch rushes)

Summer student (to help with deliveries)

Why this hybrid model is excellent for your rural business:

Saves money: you only pay for what you need. There's no need for a large office or numerous full-time salaries when you're just starting out.

Super flexible: you can grow or reduce your team easily depending on how busy it is. This is crucial for managing costs and adjusting to changes.

Access to top talent: even if your small town doesn't have a full-time expert in a certain area, you can hire them remotely or for specific visits as "hired help."

Clear roles (even when small): the simple pyramid model ensures everyone in your core team knows their responsibilities, helping to prevent confusion.

Better for safety: this is very important!

Someone is in charge: with clear roles, you know who is responsible for maintaining safety.

Quick decisions: if there's a safety issue (such as a broken machine), you can resolve it swiftly because there are fewer layers of management.

Easy to get safety help: if you're undertaking something new and risky, you can hire a safety expert (from your "hired help" leaf) to ensure you're doing it correctly. This is much more affordable than having a full-time safety officer if you don't always need one.

Everyone understands the rules: with fewer core team members, it's easier to ensure everyone is aware of the safety rules. You also need to ensure your "hired help" and "as-needed" crew understand them too, which involves proper training for all!

By employing this clever shamrock-pyramid approach, your small rural business can operate leanly, be agile in growth, and maintain a safe and happy team. It’s a winning strategy for laying a strong foundation for your future success!

Snapshot - Rapid Hazard & Risk Check

Protect your business with a Snapshot - Rapid Hazard and Risk Check. We provide a quick, professional health and safety review to find your biggest risks and compliance gaps. Our service is designed to give you clarity and peace of mind without a huge commitment. Get actionable recommendations and a clear path to a safer workplace. Find out where you stand today!

Our Snapshot - Rapid Hazard and Risk Check

At Active8hss, we created our Snapshot - Rapid Hazard and Risk Check to give you a fast, clear look at your company’s safety status. This condensed review helps you quickly understand your strengths, weaknesses, and what you need to focus on right away, all without a major commitment.

Here’s what our Snapshot includes:

Policy and Document Review: We'll quickly review your main health and safety policies and emergency plans. Our goal is to find any obvious gaps in your paperwork and make sure your basic documents meet legal requirements.

Brief Site Walkthrough: We'll do a quick, non-disruptive walk-through a key work area, like your office or workshop. This is a visual check to spot common hazards, such as trip risks or poor housekeeping, to highlight immediate concerns.

Basic Compliance Checklist: We'll give you a simple checklist of safety rules for your industry. We can then review your answers or check them against what we saw during our walkthrough to identify areas where you might not be in compliance.

Risk Discussion: We'll talk with your management team to hear what they believe are your top safety risks. This helps us compare your view with what we observed.

Concise Summary Report: You’ll get a short, easy-to-read report summarising our findings. It will highlight what you're doing well, point out key areas for improvement, and offer actionable recommendations. The report will also suggest next steps for building a stronger safety program.