Unseen Dangers: Why Small Businesses Can't Afford to Be "Risk Blind" to Confined Spaces

In the world of occupational health and safety, the term "confined space" often conjures images of deep, industrial-scale environments—sewers, massive storage tanks, or underground mines. These are the classic, high-risk scenarios that major corporations with dedicated safety departments are well-versed in handling. However, this narrow perception has created a dangerous blind spot for small businesses, many of which are unknowingly putting their employees at risk by failing to recognize the confined spaces that exist in their own operations. This "risk blindness" is a pervasive and perilous issue, leading to a disproportionate number of preventable injuries and deaths in Canada each year.

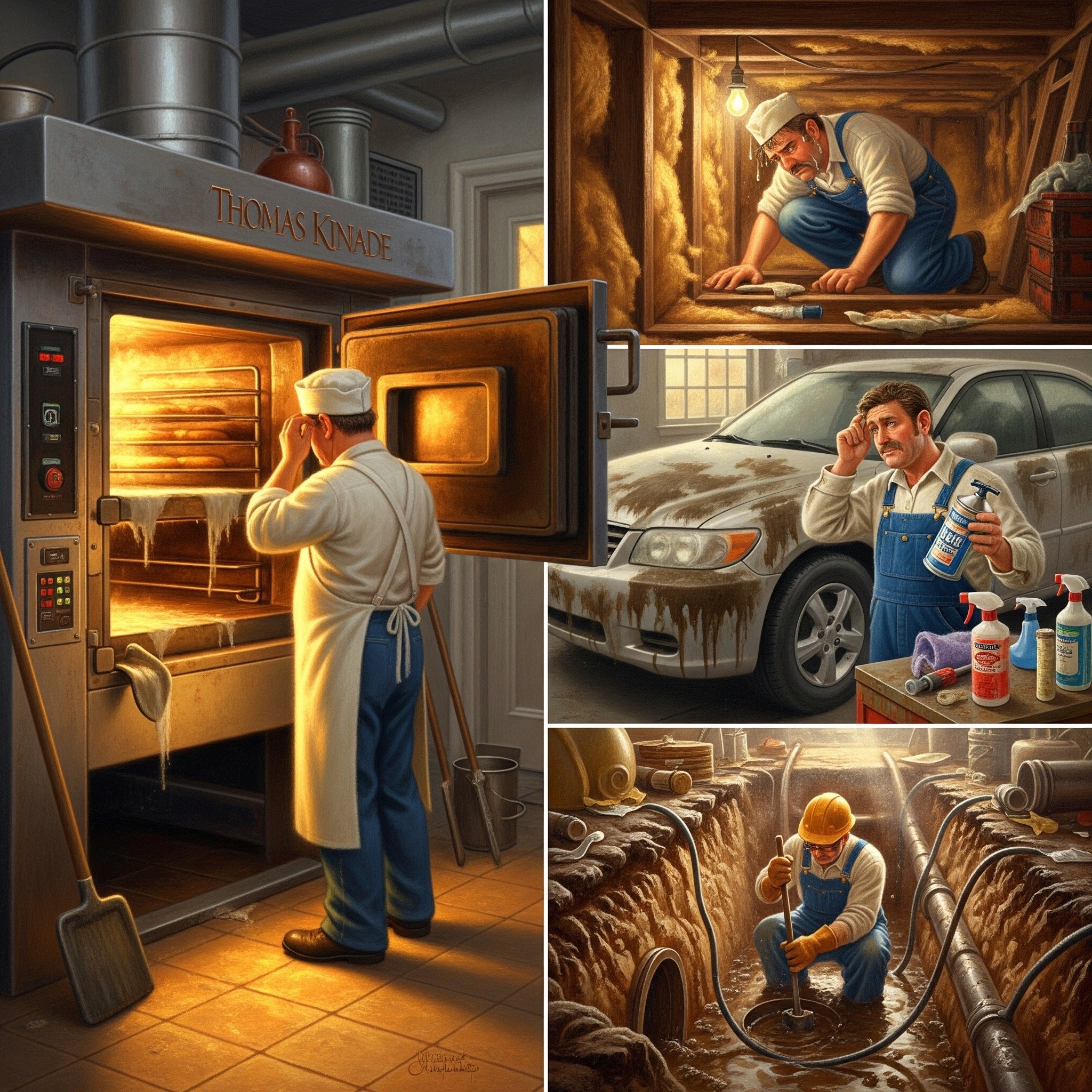

The core of the problem lies in a failure to perform a proper risk assessment and apply a standardized definition. A confined space is not defined by its industry, but by three simple criteria: it's large enough for a person to enter and work, has a limited or restricted means of entry and exit, and is not designed for continuous human occupancy. When small business owners, from bakers to contractors, look past the obvious and apply this definition to their unique work environments, the reality of the risk becomes startlingly clear.

Consider the neighborhood bakery, a pillar of the community. The owner, focused on fresh-baked goods and customer service, may never have considered that a task as routine as cleaning the oven could be a life-or-death situation. Yet, a large commercial oven meets all the criteria of a confined space. If an employee must physically climb inside to scrub away residue, they are entering a space with a single, limited exit. The danger is compounded by the use of potent cleaning chemicals in this enclosed environment, which can rapidly create a hazardous atmosphere. Without a proper risk assessment, ventilation, and a documented entry plan, what seems like a simple chore becomes an incredibly dangerous undertaking.

Similarly, a small construction company might be working on a residential project, believing they are operating in a low-risk environment. But a crew member tasked with laying piping in a utility vault, a storm drain, or even a deep trench is entering a confined space. These spaces often contain hidden dangers like explosive gases, a lack of oxygen, or the potential for engulfment by collapsing soil. Small businesses, particularly those operating on a tight budget, may skip the crucial step of air quality testing, continuous monitoring, and having a dedicated attendant outside the space. This is a gamble with their employees' lives—a gamble they don’t even know they're taking.

While a car detailer might not be dealing with a traditional confined space—a car's interior allows for easy entry and exit—they are not without their own hazards. The use of powerful chemicals in a small, enclosed area can quickly create an unhealthy atmosphere. The lesson here is that even when a space doesn't fit the confined space definition, the principles of risk assessment still apply. Proper ventilation, personal protective equipment, and a clear understanding of chemical hazards are non-negotiable, and a risk-blind attitude towards these issues can lead to acute respiratory problems or other serious health effects.

The human cost of this risk blindness is staggering. Statistics from Canadian safety organizations reveal the brutal reality: over 100 people die in confined spaces in Canada every year, with the vast majority of these deaths resulting from an atmospheric hazard. What’s even more tragic is that a significant percentage of these fatalities are among would-be rescuers—colleagues who, in a moment of panic and without proper training, attempt to save a stricken worker and become a victim themselves. From 2011 to 2015 alone, there were nearly 12,000 lost-time injuries, a number that speaks volumes about the frequency and severity of these incidents.

These statistics underscore the vital importance of proper confined space training and a thorough risk assessment. For small businesses, this isn't about bureaucracy; it's about survival—both for the business and for its employees. Adopting a proactive safety culture, where every work environment is analyzed for its potential risks, is the only way to prevent these tragedies. The danger isn't always in a deep mine or a massive tank; sometimes, it's just a few feet away, hidden in plain sight, waiting for a business to become risk blind.